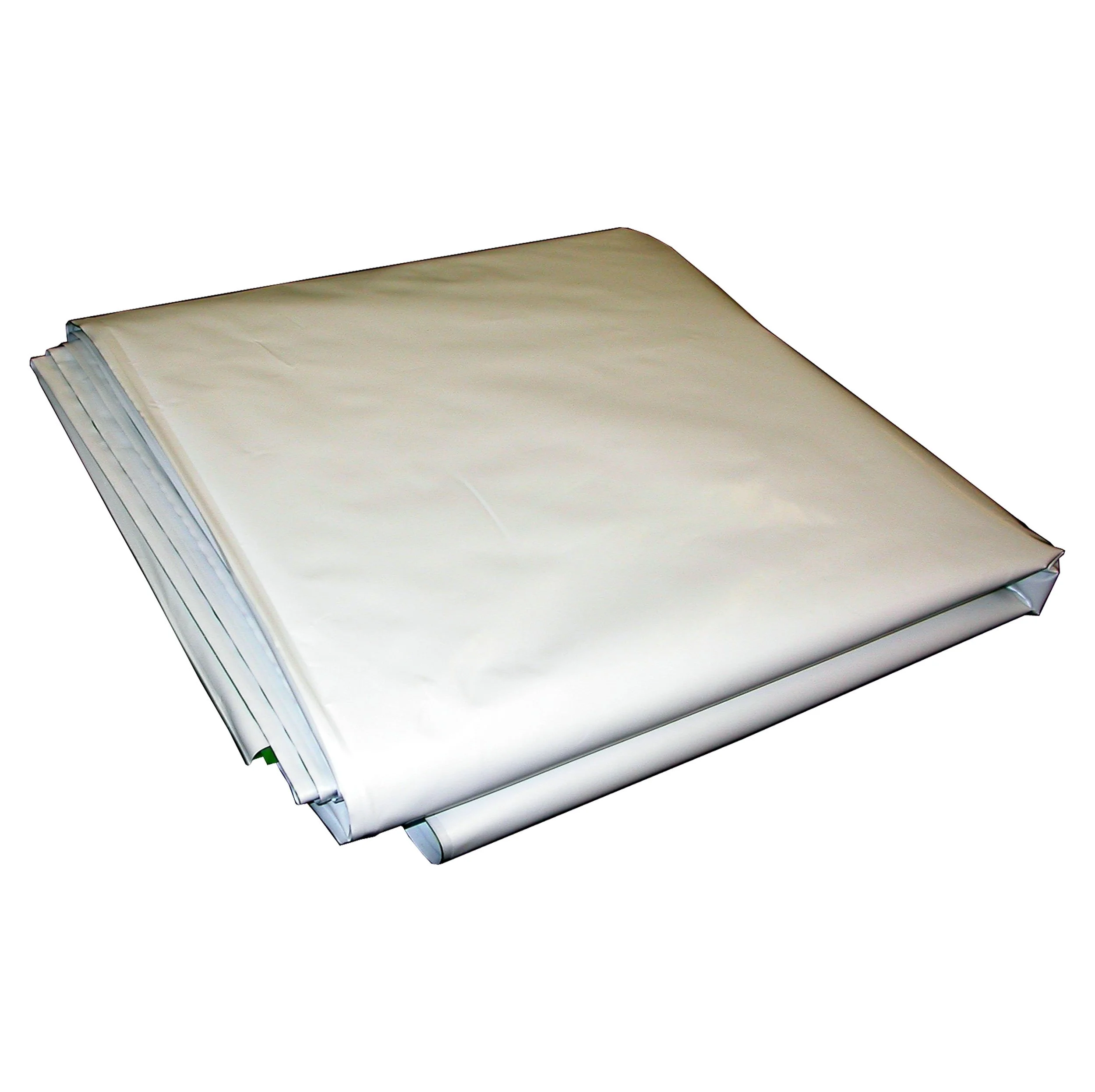

Barrier Blankets

Barrier Blankets are made from two or more panels of standard roll stock heat-sealed together on one edge. They are faster to use and more cost-effective than onsite cover fabrication from roll stock.

Our blankets are ideal for items that don’t require a glove fit and that need a packaging solution quickly. They are also a good choice when a uniform look is unimportant.

Made-to-Order

You pick the size, material, and any special features; or have one of our packaging experts guide you to the best solution.

How it Works

Step 1

Lay the blanket on top of a pallet, with the center of the blanket in the center of the pallet. Place the item to be protected in the middle of the blanket.

Step 2

Lift the edges of the blanket to enclose the item, then use a manual heat sealer to close.

Step 3

Pinch together the open ends and continue heat sealing.

Specify Your Requirements

Materials

Barrier blankets are typically made from multilayered laminations that provide a high level of barrier. Provide us with a material specification, or allow us to recommend a material and thickness to help achieve your packaging goals.

Closure Methods

Barrier blankets are most commonly closed using a manual heat sealer or pressure-sensitive tape. Choosing the right closure depends on the level of barrier protection required, how frequently the items will be accessed, how the end-user will handle the product, and more.

Optional Features & Secondary Operations

We offer a variety of inline and secondary features like vacuum or pressure relief valve installation, VCI emitters or desiccant inclusion, window installation, and more.

No Detailed Dimensions

Barrier blankets offer flexibility because they aren’t a glove fit. While we need precise overall dimensions, we typically don’t require a technical drawing or detailed measurements to move ahead.

No Heavy Rolls

Using a barrier blanket eliminates the need to keep and manipulate heavy rolls of material onsite.

Easy Transport

Our barrier blankets are folded and packed to make transport to the packing site convenient.