Handheld Heat Sealers Vs. Heat Seal Machines

Achieving a Hermetic Seal

Parameters must be developed for a sealing device to achieve optimally strong, airtight seals. These parameters define a specific temperature to be applied under a specific pressure for a specific duration of time.

We achieve this consistently by using equipment with calibrated controls for temperature, pressure, and time. This greatly reduces human error and gives us capabilities unmatched by DIY methods.

Cons of Handheld Devices

Human error often leads to inconsistent heat seal quality with handheld equipment.

Satisfactory heat seals are possible if the operator diligently pursues consistency in pressure and time; however, repeatedly squeezing or pushing down on a manual sealer with the same pressure and amount of time is difficult.

When time and pressure are inconsistent, the seal quality can vary from one point to another.

Pros of Handheld Devices

That said, there is a time and place for using a professional handheld heat sealer, and we realize that some applications benefit from using a manual device.

You can achieve a good-quality hermetic heat seal with consistent pressure and time. A handheld device also allows the operator to reach tight corners or irregular film configurations more precisely than some machinery.

No matter what equipment you are using, always practice on pieces of scrap material and change the time, pressure, and temperature settings until you achieve the right seal quality.

Safety

Any heat sealer that employs constantly hot seal bars, whether a handheld manual sealer, a tabletop or floor-mounted sealing machine with controls for heat, time, and pressure, or fully automatic sealing equipment, should only be used for sealing multi-layered barrier materials.

Mono-layered materials, such as what sandwich bags are made from, will stick to the sealer jaws and cause a mess and possible injury. Barrier materials are produced with a higher heat-resistant film layer over the sealant layer, such as NYLON, Polyester, or even paper, and therefore do not stick to the seal bars.

How to Choose a Handheld Device

Choosing the right heat-sealing device will help set you up for success. Consider these types of devices before making a purchase:

Rotary Band Sealers

Rotary band sealers (RBS) can produce hermetic seals, but they are challenging to use on complex covers with multiple corners (especially inside corners) or curves. RBS are a good fit for long, straight seals or for closing pouches.

Hand Irons

Hand irons are heated metal surfaces with a Teflon-coated fabric cover and insulated handles available in numerous sizes and shapes. They produce the least consistent heat seals of available equipment but are handy for sealing a patch onto a cover or bag. For the best results when using a hand iron, place a sheet of 1/4” thick, 90 durometer, red silicone rubber under the area being sealed to act as an anvil.

Plier-Style

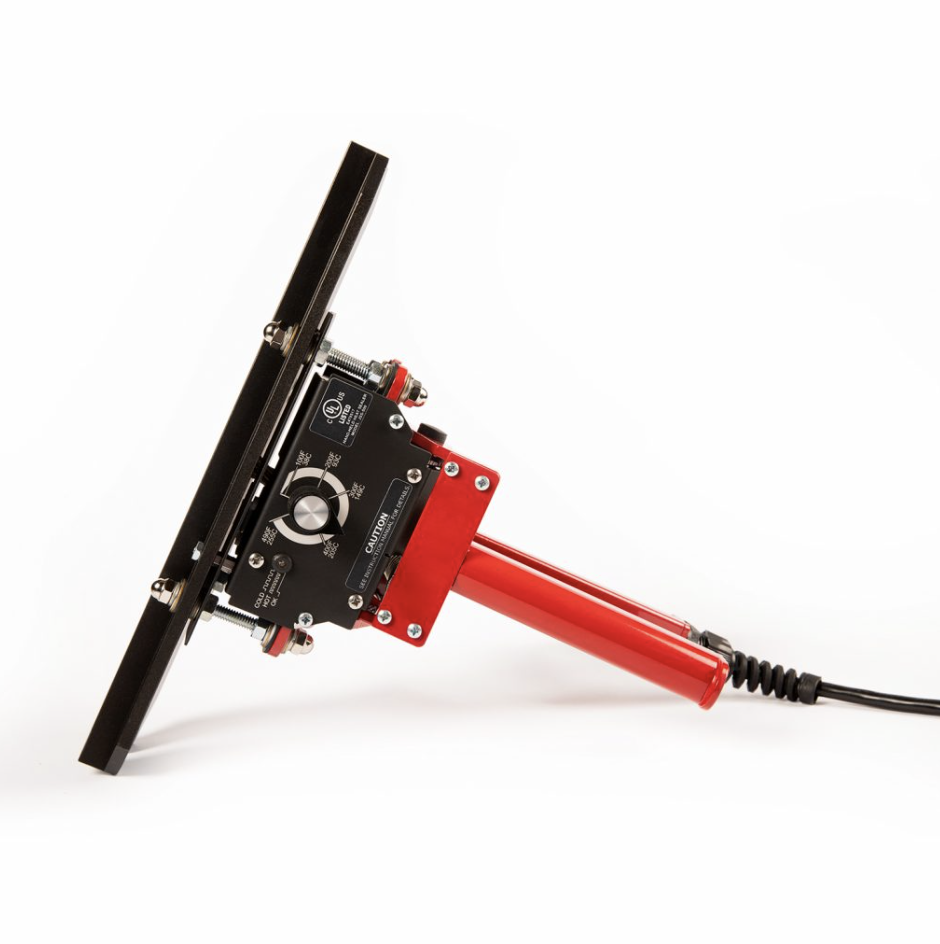

Plier-style handheld sealers are the most reliable and user-friendly devices. When consistent time and pressure are applied, these sealers can produce hermetic seals on long straights, internal or external corners, and curves. Below are two of our top picks. The JSS500 is a heavy-duty workhorse capable of long-term constant use, while the KF200-CS is better suited for occasional use.

JSS500

KF200-CS

When to Hire A Convertor

Every application has a unique set of packaging requirements. At Heritage Packaging, we choose our equipment and tools based on those requirements. Some products run entirely on machines, while others are hand-fabricated using only manual devices or a combination of both.

If you've got tens of thousands or hundreds of thousands of items to be made, or if the one item you need is so important and serves such an important cause that it needs to be perfect then we recommend hiring a professional like Heritage Packaging to do the work for you.

Example of a pneumatically powered thermal impulse heat sealer with table space that allows materials to lay at rest during the sealing process, assuring hermetic seals.

Photo of our fitment installation heat sealer, which allows us to precisely regulate time, temperature, and pressure.

Wondering if you should hire a flexible material convertor or purchase a handheld manual device?

Schedule a free 30 minute consultation and we’ll guide you to the perfect packaging solution.